My Research - Currently editing

My research area, which can largely be described as Industrial Mathematical Modelling, is concerned with building mathematical models to describe microfibre release from clothes and filtration of these microfibres in a washing machine. Microplastic fibres from our clothes make up around 35% of all of the microplastics in the oceans, and it is estimated that each person in the UK produces on average 243g of microplastic fibres per year when washing their clothes in a standard washing machine. Thus, many countries have started to introduce laws requiring new washing machines to filter out microfibres when draining waste water.

Working in collaboration with Beko plc, we are exploring simple mathematical models to determine how to minimise microfibre release and maximise filtration efficiency within a washing machine, defining my research into two main processes, generation and filtration of microfibres.

Microfibre Release

Inside a washing machine drum, various mechanical forces act on the clothing to cause the generation of loose microfibres. We have been constructing models to describe the underlying mechanics that help and hinder release. We started our investigation by looking at a continuum model of erosion due to water shear stress, and we are currently looking at building a model for individual fibre release. These represent our continuum and discrete based models.

Continuum Model

We started our understanding of microfibre release by assuming that we have a small layer of fibres, or fuzz, on the surface of a piece of clothing. We treat this layer as a continuum, and assuming that the height of this layer is small compared to the length of the material, then we may utilise a lubrication limit for the flow over this material. We have assumed that the flow over the material is providing some shear stress to the material and eroding away material when this overcomes some critical friction or shear stress.

Therefore, our dimensionless erosion law becomes

We also have conservation of fluid, in the form of the following Reynold's equation,

which tells us the flow dyanmics in a long and thin channel.

Microfibre Filtration

Ricochet Separation

In addition to fibre generation, we are also exploring a new method of solid-fluid inertial separation called ricochet separation, to increase the life expectancy of the current microfibre filter within Beko and Grundig washing machines. In 2021, Grundig, which is a sister company of Beko and owned by Turkish household appliance manufacturer Arçelik, were the first company to produce a internally installed microfibre filter, called a Fibercatcher, capturing up to 90% of microfibres. We want to prolong the life expectancy of this microfibre filter so that the consumer would need to replace the filter less often.

We are exploring a technique used by manta ray fish to expel water when ingesting plankton rich water, which has been studied in [1]. Within a washing machine, this method would be utilised by removing some volume of microfibre free water from dirty fibrous water decreasing the pressure drop over the Fibercatcher filter and inturn increasing the lifespan. By utilising mathematical techniques coupled with computational fluid dynamics, we will study the dynamics of the flow and particle behaviour, and eventually optimise the design parameters to increase filtration efficiency.

We have been trying to understand the simplest model for the flow and ricochet behaviour. We have been modelling the high Reynolds number flow (Re ~ 2700) via steady, incompressible Navier-Stokes equations,

and particle force balance,

When a particle comes into contact with the curved surface of the geometry, we have assumed that the particle bounces balistically, where the angle of reflection is equation to the angle of reflection.

We have found the concept of ricochet separation to be most effective for larger Reynolds number, angle of gill structure and number of gills via CFD. We started our investigation of this process through COMSOL CFD, to gain an understanding of how this would work to allow for maximum flow through the branches and minimum particles.

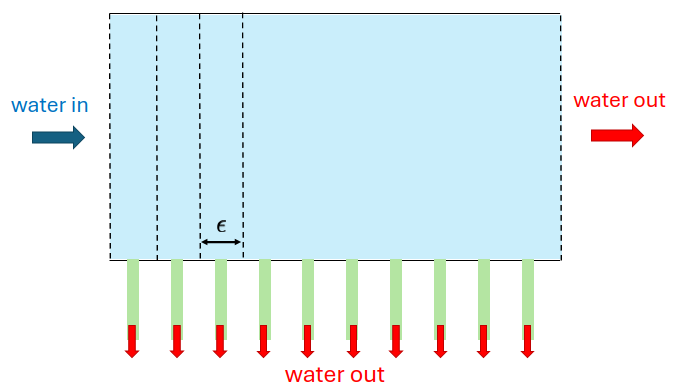

Method of Multiple Scales

From our initial CFD simulations of Beko's ricochet device, we noticed that the flow looks somewhat periodic over a cell, the width between each repeatable domain. It seems like we would be able to use some form of homogenisation techniques to smooth out the geometry of the branched channel gills into an effective boundary condition on the bottom wall in a simpler domain.

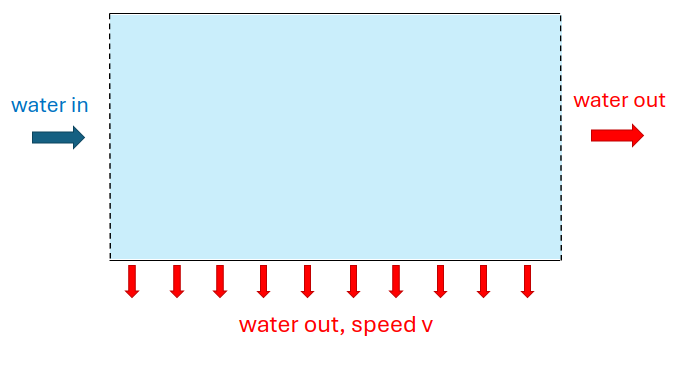

As an initial point of studying the flow and finding this boundary condition, we consider a simpler domain for the ricochet device flow. We construct a domain of a series of T-Junctions, and apply a given outlet pressure, $$p = \mathcal{P}_\text{out},$$ representing the pressure of the Fibercatcher filter which the dirty water is flowing into, and constant inlet flow velocity. From this structure, it has made it an easier starting point to find this effective boundary condition, given by a Darcy like flow,

We consider various distiguished limits for the flow regime and boundary layer sizes. We explore

Case 1

We have utilised methods of multiple scales, otherwise called homogenisation, to solve for the flow in this domain which allowed us to calculate the flow behaviour more efficiently. This method involves boundary layer anaylsis, multiscales analysis, complex analysis and matched asymptotics to identify an effective boundary condition on the wall of simple channel flow. We have found that the `clean water' cross flow which is expelled out of the bottom branched channels is effectively a Darcy like flux condition, given by something that looks like

Given this boundary condition, it will allow us to optimise more efficiently via faster parameter sweeps.

To find an analytical expression for the effective boundary condition, and flow profile, we look at the homogenized problem in the limit of small cell size.

T-junction domain for ricochet flow

Homogenised boundary condition, as $$\epsilon \rightarrow 0$$

Case 2

Particle Bounces

We introduce particle bounces to our homogenised flow field and prescribe some formula as the particles bounce to represent how they react with the wall to create the ricochet effect and where some particles are lost through the branches.